The Breakthrough Path of Zhejiang ROBO New Materials: A Benchmark in the Capacitor Industry Zhejiang ROBO New Materials Co., Ltd.’s success in the capacitor industry is not due to scale like some giants, but rather to its extreme focus on a niche market and technological breakthroughs, making it an indispensable key link in the industry chain. Its core competitiveness can be summarized as follows:

1. Deep Technical Expertise: Processes Targeting Industry Pain Points

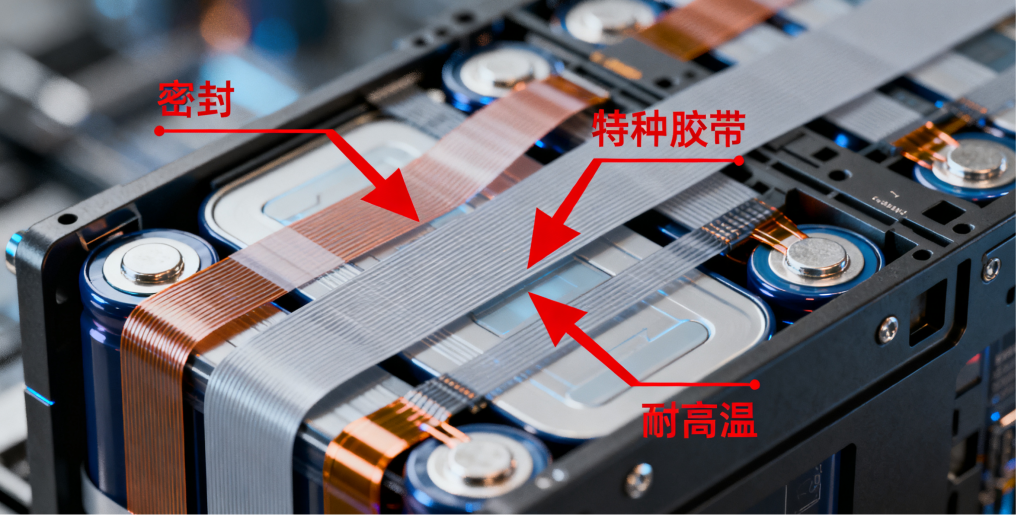

The core issues with capacitor tapes focus on three main problems: insulation performance degradation, dimensional changes at high temperatures, and failure due to electrolyte corrosion. These are precisely the areas that Zhejiang ROBO New Materials is dedicated to tackling.

Since its establishment, Zhejiang ROBO New Materials has accurately pinpointed this niche market. Rather than pursuing a “broad-spectrum layout,” it focuses on the research, development, and production of special adhesives and coating materials. Its products cover the three key stages of capacitor core fixation, electrode insulation, and packaging sealing, ensuring structural stability, electrical isolation, and sealing performance, respectively. Ultimately, this has created a comprehensive solution suitable for high-end applications, addressing the industry’s core pain points caused by traditional materials that shorten capacitor lifespan and increase failure rates.

2. Strong Technical Barriers: Product Performance Reaches International Standards

The competitiveness of ROBO New Materials’ products is far from merely meeting basic usability standards; instead, they benchmark against or even surpass leading international brands in key performance indicators, creating hard-to-replicate technical barriers. In terms of high purity and insulation, their products have extremely low levels of impurity ions (such as chloride and sodium ions), effectively preventing risks of increased dielectric loss, reduced insulation resistance, or breakdown in capacitors caused by adhesive contamination. Regarding temperature stability, the products can withstand the heat generated during capacitor operation and manufacturing for extended periods (from 85℃ to 150℃, or even higher) without decomposing, losing adhesiveness, or cracking, ensuring the long-term reliability of capacitors.

3. Deeply Bind with Top-Tier Clients to Create a “Lighthouse Effect”

Client Binding: Anchor with the global leading supply chains to release the “lighthouse effect” through benchmark cooperation.

The strength of a client is the ‘litmus test’ of a company’s strength. ROBO New Materials’ core competitiveness lies in its deep integration into the global top-tier supply chains, which in turn releases a powerful “lighthouse effect.”

ROBO New Materials has entered the core supply chains of the world’s top capacitor manufacturers, with partners including domestic leader Aihua Electronics, Japan’s benchmark Kyocera, Nichicon, Panasonic, Jingshan Electronics, Lilong Electronics, and other leading enterprises. The certifications are extremely stringent, serving as an ‘industry litmus test.’ ROBO has not only successfully passed them but also achieved long-term stable supply. Endorsement from top-tier clients has established its industry trust benchmark.

In terminal applications, its materials have further penetrated into the world’s top brands: through automotive capacitors, it supplies leading car manufacturers such as BYD, NIO, and Li Auto, while also entering the supply chains of Fortune 500 consumer electronics and industrial equipment companies like Huawei, Foxconn, and Haier. This full-chain coverage from ‘core materials – capacitor manufacturers – top-tier end clients’ not only strengthens its market position but also activates the “lighthouse effect” — small and medium capacitor manufacturers lower their trust costs and shorten decision cycles due to the cooperation cases with leading enterprises; some clients even use ‘whether Ruibo has entered top-tier supply chains’ as a reference for selection, helping it accelerate market share expansion.

4. Beneficiaries and Drivers of the Domestic Substitution Wave

Amid the national push for supply chain security and domestic production, ROBO New Materials actively responds to supply-side structural reforms, becoming a key force in enhancing the quality of high-end material supply. The company has successfully broken the technological blockade and market monopoly of Japanese firms over high-end capacitor materials, overcoming bottlenecks and achieving industrial breakthroughs in high-end electronic chemicals.

Relying on its independent R&D system, ROBO New Materials can develop specialty adhesives and coating materials resistant to electrolyte corrosion tailored to the stringent needs in fields such as new energy and semiconductors, effectively supporting the stable operation of capacitor products. By promoting the localization of high-end materials, the company has reduced domestic dependence on imported high-end capacitor materials to below 30%, not only lowering procurement costs for downstream enterprises but also ensuring production continuity amid supply chain fluctuations.

ROBO New Materials’ material solutions help domestic capacitor companies enhance competitiveness, drive industrial upgrading towards high-end development, and make substantial contributions to strengthening the autonomy of the industrial chain and national supply chain security.

5. From ‘Material Supplier’ to ‘Value Partner in the Industrial Chain’ — ROBO New Materials’ Value Leap

The strength of Zhejiang ROBO New Materials lies not in being a simple ‘tape supplier’ but in becoming a ‘material solutions expert’ deeply rooted in the capacitor sector.

The company addresses industry pain points through technical expertise, builds product foundations on reliable performance, and meets customer needs with agile service. In the seemingly niche yet critical material segment of capacitor manufacturing, it establishes competitive barriers. Ultimately, ROBO New Materials has not only earned deep market recognition and industry-leading status in the global capacitor materials sector but has also completed the upgrade from ‘selling tape’ to ’empowering the industrial chain,’ becoming an indispensable value partner in the autonomy and controllability of the industrial chain.