New Energy Lithium Battery Industry

Our capacitive tapes deliver precise, reliable, high-temperature resistant solutions across electronics, automotive, and high-precision industries.

- Home

- New Energy Lithium Battery Industry

New Energy Lithium Battery Industry

The new energy lithium battery industry is a strategic emerging sector that integrates R&D, production, application, and recycling. The upstream focuses on resources and materials, the midstream on cell manufacturing and system integration, and the downstream on diverse application scenarios.

Key Benefits

- Upstream: Lithium, cobalt, nickel; cathode, anode, electrolyte, separator.

- Midstream & Downstream: Cell & BMS; NEVs, energy storage, electronics, tools.

How it Works

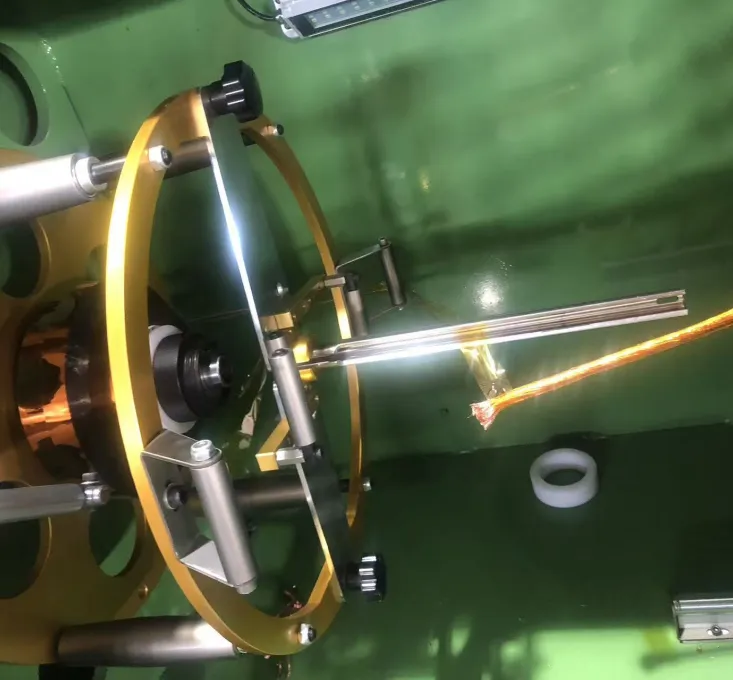

High-temperature tapes (200–500℃ resistant, insulating, and corrosion-proof) are essential auxiliary materials in lithium battery production, ensuring safety and reliability across the entire process.

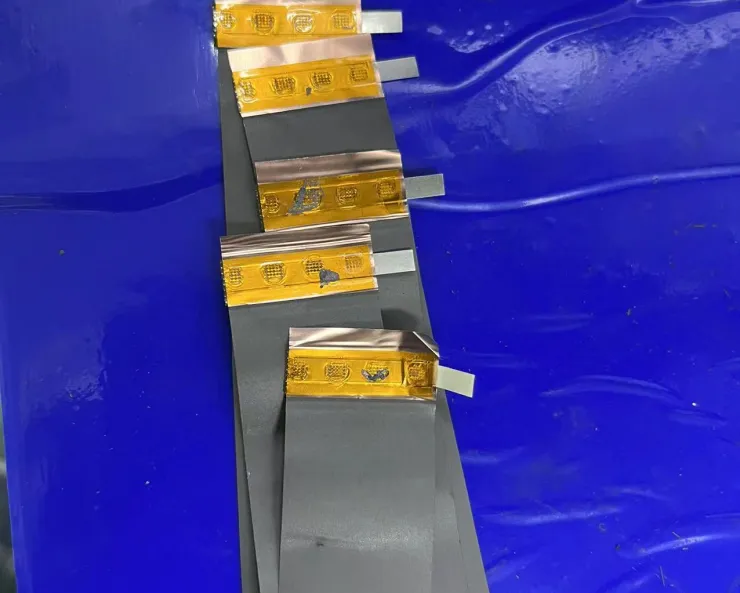

Cell Manufacturing

Fix pole pieces, shield non-welding areas, prevent solder slag and displacement.

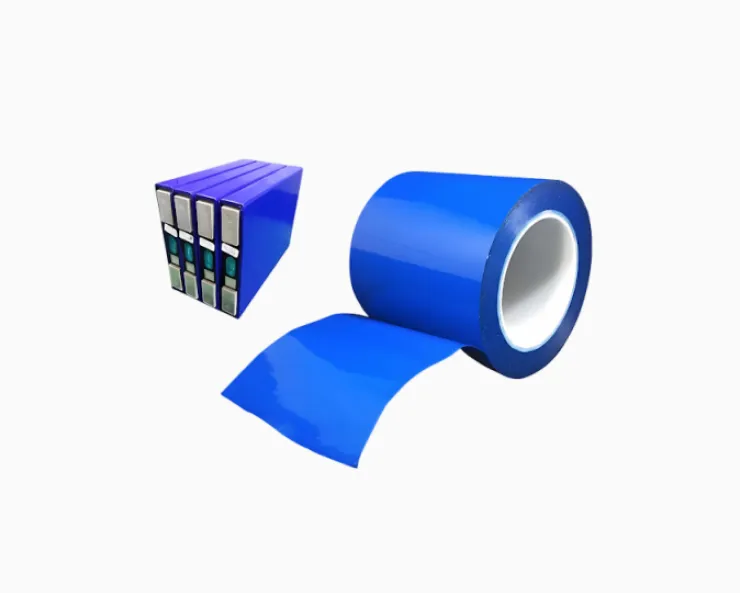

Module Assembly

Secure cells and heat dissipation parts, insulate to avoid short circuits.

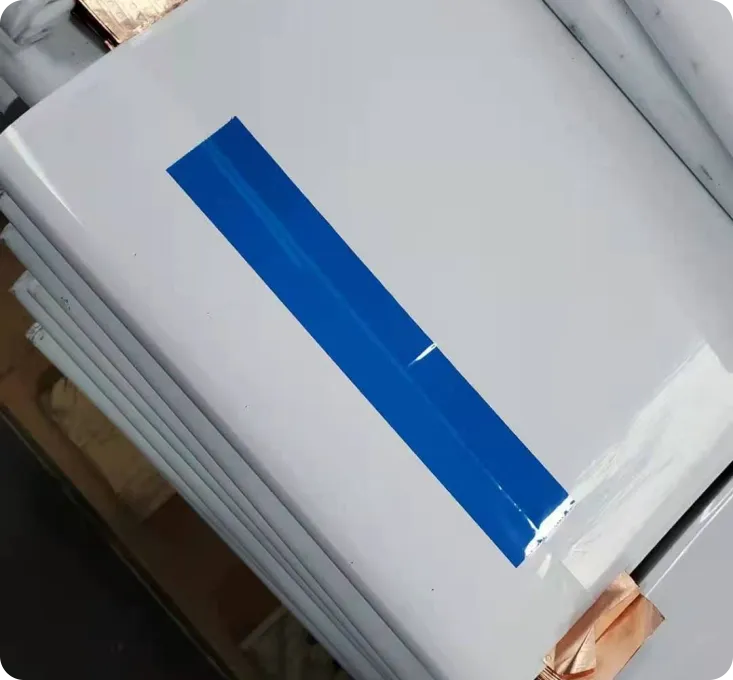

Pack Packaging

Protect battery case parts, prevent scratches and heat damage.

Performance

High-temperature resistance, insulation, and chemical durability for stable production.

Core Element for

Innovation & Excellence

Essential Properties

High-temperature tape, resistant to 200–500℃, offers insulation and chemical corrosion resistance, serving as a critical safeguard throughout the lithium battery production process.

Precision in Cell Welding

Fixes pole pieces,shields non-welding areas,and prevents contamination, guaranteeing welding accuracy and performance.

Safety in Module Assembly

Secures cells and heat dissipation parts,while isolating conduction risks to eliminate hidden short-circuit dangers.

Protection in Pack Packaging

Shields critical components from scratches and heat damage, preserving structure and appearance of finished batteries.

Comprehensive Solution

Securing and insulating electrode tabs: In the internal structure of batteries, PI tape is often used to secure the positive and negative electrode tabs. It prevents the tabs from being damaged by shaking or from causing a short circuit by coming into contact with other parts during battery charging and discharging. Its excellent insulating properties and corrosion resistance ensure long-term stability in an electrolyte environment

“Termination Tape” is primarily used in lithium battery manufacturing to secure, insulate, and protect the electrode tabs, plates, and the termination part of the wound core. It is a special pressure-sensitive adhesive tape, typically made of a film base material such as PET, PP, or PI, coated with a special adhesive that is resistant to electrolyte

The blue tape wrapped around the outside of a prismatic lithium battery primarily serves the purposes of insulation and protection. The casing of a prismatic lithium battery is typically a conductive aluminum shell. When multiple cells are arranged densely within a battery module or pack, the blue tape effectively isolates the cell casings, preventing contact between the cells or with other metal structural components of the module, thereby enhancing the safety of the entire battery system. Anti-puncture: The stamped or welded edges of the aluminum cell casing may have burrs. The blue tape covers these sharp edges, preventing them from puncturing the insulation layer of adjacent cells.