Industrial/Electronic Spraying

Our capacitive tapes deliver precise, reliable, high-temperature resistant solutions across electronics, automotive, and high-precision industries.

- Home

- Industrial/Electronic Spraying

Industrial & Electronic Spraying Technology

Industrial and electronic spraying is a versatile surface treatment process that applies functional coatings to enhance protection, performance, and aesthetics of products.

Key Benefits

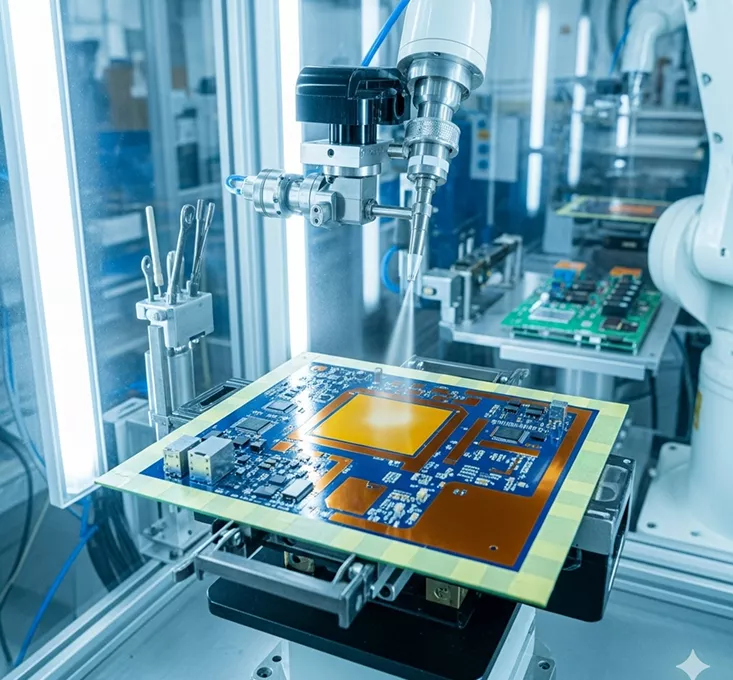

- Electronics Applications : Provides insulation and protective barriers for circuit boards and components, ensuring stable operation in complex environments.

- Industrial Applications : Offers surface protection and decoration for machinery, automobiles, and household appliances, improving durability and appearance.

How it Works

High-temperature tape provides reliable masking and isolation in extreme heat, ensuring clean, precise, and residue-free results during industrial and electronic spraying, curing, and baking processes.

Heat Resistance

Withstands high temperatures during spraying, curing, and baking.

Masking & Isolation

Protects areas from paint, powder, or coatings.

Stability

Maintains shape and adhesion without deformation.

Clean Removal

Leaves no residue, ensuring precise edges and processing.

Core Element for

Innovation & Excellence

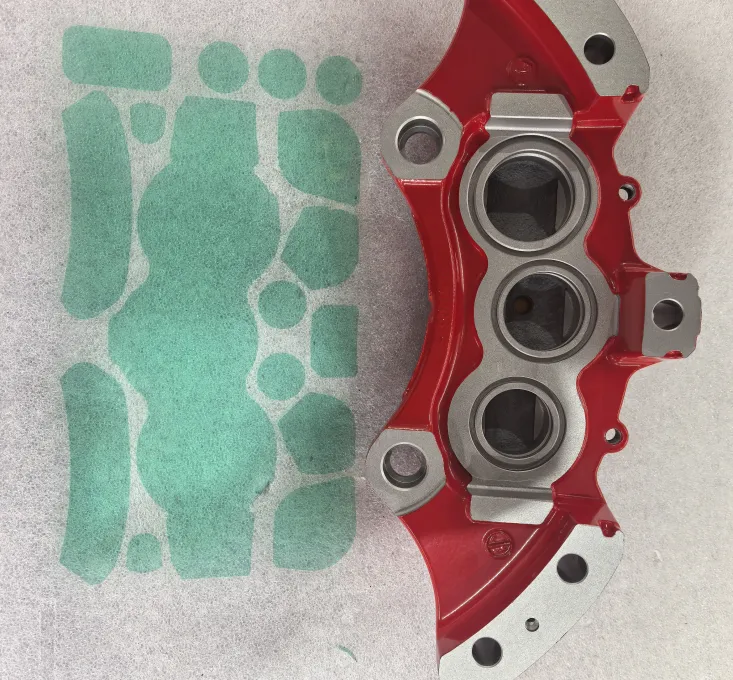

Precise Masking & Surface Protection

Covers only target areas, preventing unwanted coating and keeping surfaces clean.

High-Temperature Resistance

Can withstand spraying, curing, baking, and other high-temperature processes, remaining stable without wrinkling or carbonization.

Surface Protection: Prevents paint, powder, or chemicals from adhering to areas that do not require treatment, keeping surfaces clean.

Residue-Free Removal

Can be cleanly removed even after high-temperature operations without damaging the workpiece, saving time and cost for subsequent cleaning.

Improved Yield & Efficiency

Ensures neat coating edges and consistent processes, reducing rework and enhancing product quality and production efficiency.

Comprehensive Solution

Polyimide tape / Kapton tape is resistant to high and low temperatures (-269°C to +300°C) and can withstand spraying, curing, and baking processes. It maintains stable adhesion without wrinkling or carbonizing, ensuring smooth processing. It prevents paint, powder, or chemical agents from adhering to non-sprayed areas, protects sensitive surfaces, and reduces post-process cleaning. After high-temperature operations, it can still be removed cleanly without damaging the workpiece, saving cleaning time and costs.

PET tape has a temperature resistance of approximately 150–200°C. It leverages the high strength and dimensional stability of the polyester film, along with the adhesion of the adhesive, to achieve precise masking, fixation, and surface protection of components or circuit boards during the spraying process. After spraying, it can be removed cleanly, ensuring coating accuracy and component safety.

PTFE tape, with its high temperature resistance (the PTFE film itself can withstand temperatures above 250°C) and excellent chemical inertness to solvents, acids, alkalis, and coating materials, protects component surfaces from paint or chemical exposure. Its low friction and high mechanical strength allow precise masking, surface protection, and component fixation during the spraying process. After spraying, it can be removed cleanly, ensuring coating accuracy and component safety.