Electrolytic Capacitor

Our capacitive tapes deliver precise, reliable, high-temperature resistant solutions across electronics, automotive, and high-precision industries.

- Home

- Electrolytic Capacitor

Electrolytic Capacitor

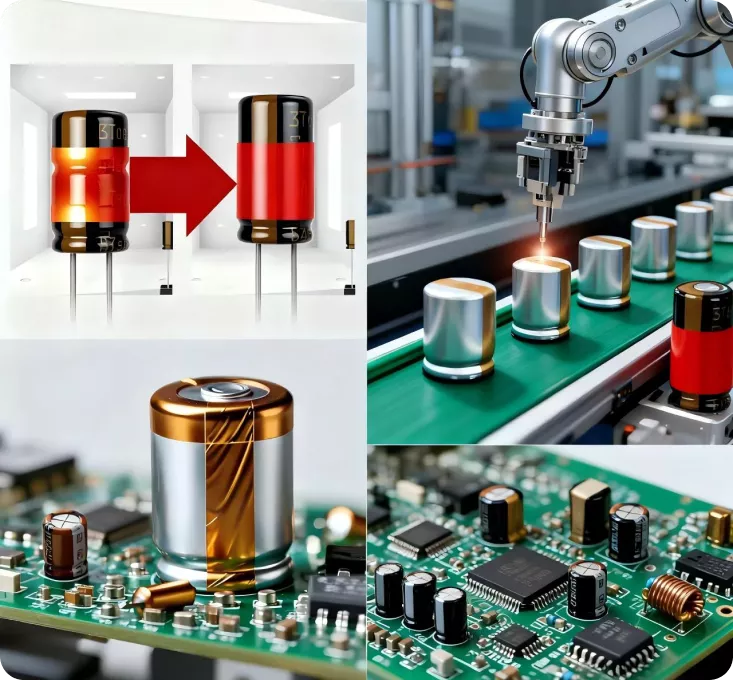

The capacitor industry integrates R&D, production, sales, and services, providing a key electronic component that stores and releases energy with functions such as AC conduction and DC blocking.

Key Benefits

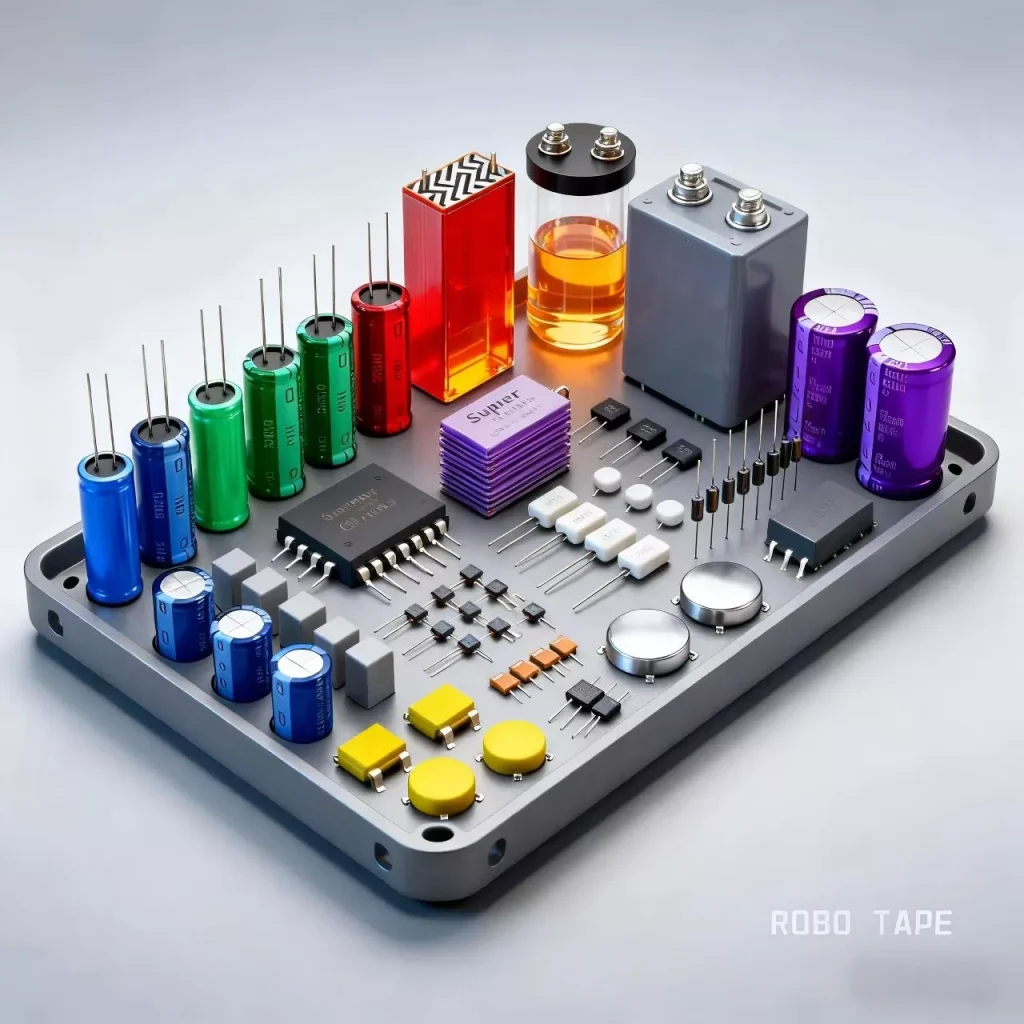

- Functions & Applications : Capacitance, voltage resistance; widely used in filtering, coupling, and decoupling.

- Types & Importance : Ceramic, aluminum electrolytic, tantalum, and film capacitors; indispensable in electronic equipment.

How it Works

High-temperature tape plays a crucial role in capacitor production, providing reliable insulation, fixation, and shielding to ensure product quality and safety.

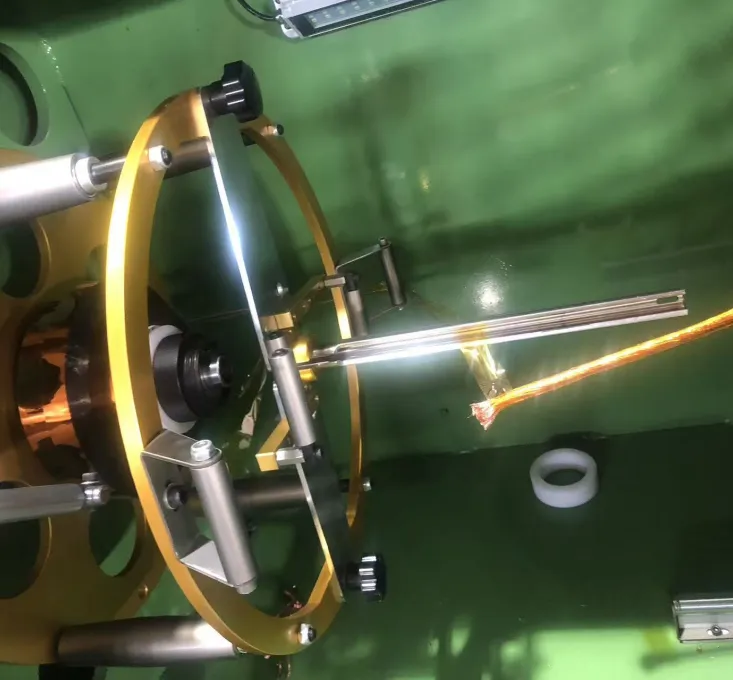

Core Winding

Fixes electrode foils and diaphragms, preventing interlayer displacement.

Pin Welding

Shields non-welding areas, avoiding solder slag damage.

Packaging

Isolates the shell from the core, enhancing electrical safety.

Overall Reliability

Ensures stable performance throughout the manufacturing process.

Core Element for

Innovation & Excellence

Key Roles of High-Temp Tape

- Its base material (such as polyimide) has high temperature resistance (usually withstanding 200-500°C), which can endure high-temperature processes in capacitor production, such as welding and curing.

- Its adhesive layer has both insulation and adhesion properties. It can not only insulate current to prevent short circuits, but also fix components stably without falling off or producing harmful substances in subsequent processes or use, thus ensuring the performance and service life of capacitors.

Comprehensive Solution

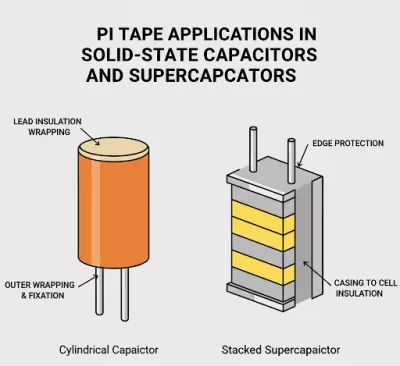

PI tape is mainly used in solid-state capacitors and supercapacitors for: insulation protection (of leads, plates, and casings), high-temperature process protection (during reflow soldering and welding), and fixation and mechanical reinforcement (for cell winding and module assembly). It is one of the key materials for ensuring the reliability and lifespan of capacitors

In aluminum electrolytic capacitors, polypropylene tapeis mainly used for:

Winding fixation (ensuring core stability)

Insulation protection (electrodes, casing, leads)

Module separation (multi-capacitor assemblies)

It is an indispensable insulating and fixing material in capacitor manufacturing.

Why does the capacitor industry choose PI tape as the main functional electronic auxiliary material?

High temperature resistance: withstands short-term temperatures ≥260 °C, suitable for reflow soldering processes.

Excellent electrical insulation: high dielectric strength ensures safe operation of capacitors

Chemical resistance: resists the effects of electrolytes and solvents.

High mechanical strength: protects the structural stability of the capacitor.