Electric Components and PCB

Our capacitive tapes deliver precise, reliable, high-temperature resistant solutions across electronics, automotive, and high-precision industries.

- Home

- Electric Components and PCB

Electric Components and PCB

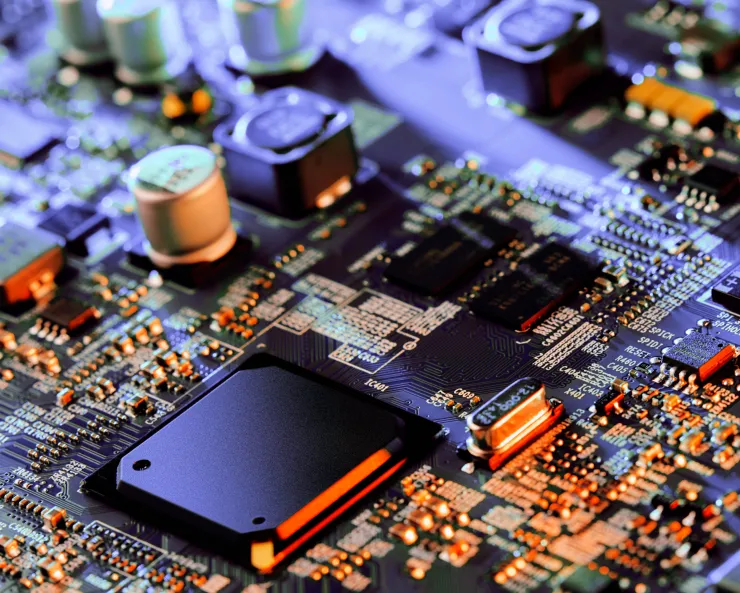

Electronic components are the basic units that make up electronic circuits. They are used to realize functions such as signal generation, transmission, conversion, control, or storage, and are the core components of electronic devices (e.g., mobile phones, computers).

Key Benefits

- Active components: Such as transistors, integrated circuits (ICs), and diodes.

- Passive components: Such as resistors, capacitors, and inductors.

How it Works

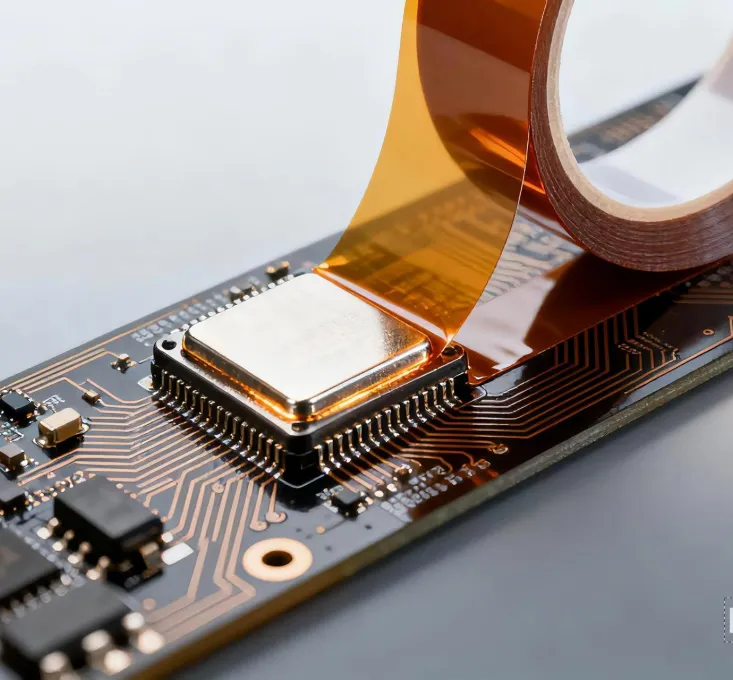

Functional high-temperature tapes combine heat-resistant substrates with special adhesives to ensure stability and performance in electronic and PCB applications.

Heat Resistance

Stable bonding at 120℃–300℃ without loss of strength.

Multi-Use

Ideal for insulation, masking, fixing, protection.

Reliable

Supports safe and consistent processes under heat.

Residue-Free

Easy removal, no residue, no damage to substrates.

Core Element for

Innovation & Excellence

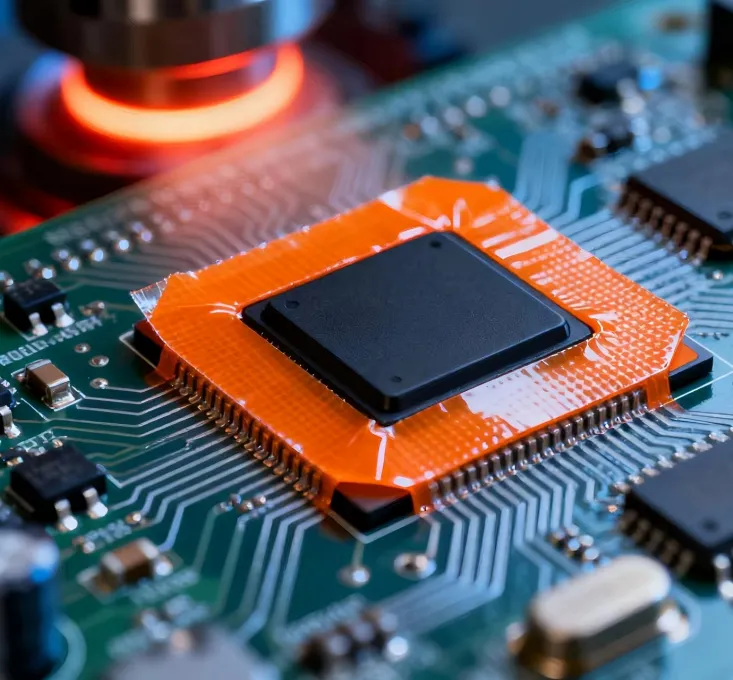

Securing High-Temperature Processes

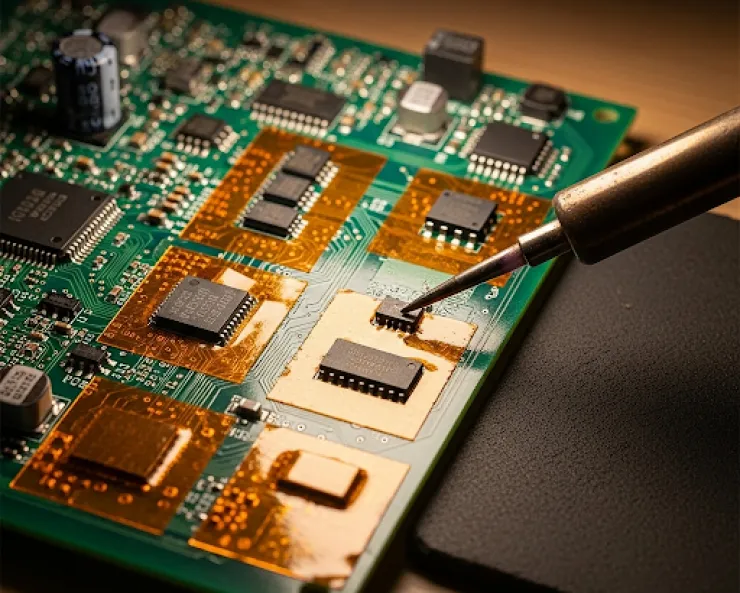

Fixes components and shields critical areas during high-temperature procedures like welding, preventing displacement or contamination and ensuring uninterrupted production.

Enhancing Product Reliability

Isolates short-circuit risks through insulation; some tapes also resist moisture, heat and aging, reducing the probability of equipment failures in later stages.

Adapting to Precision Manufacturing

Can be made into thin and narrow specifications to meet the needs of miniaturized components. Moreover, it peels off easily without residue after high-temperature exposure, without affecting subsequent processes.

Comprehensive Solution

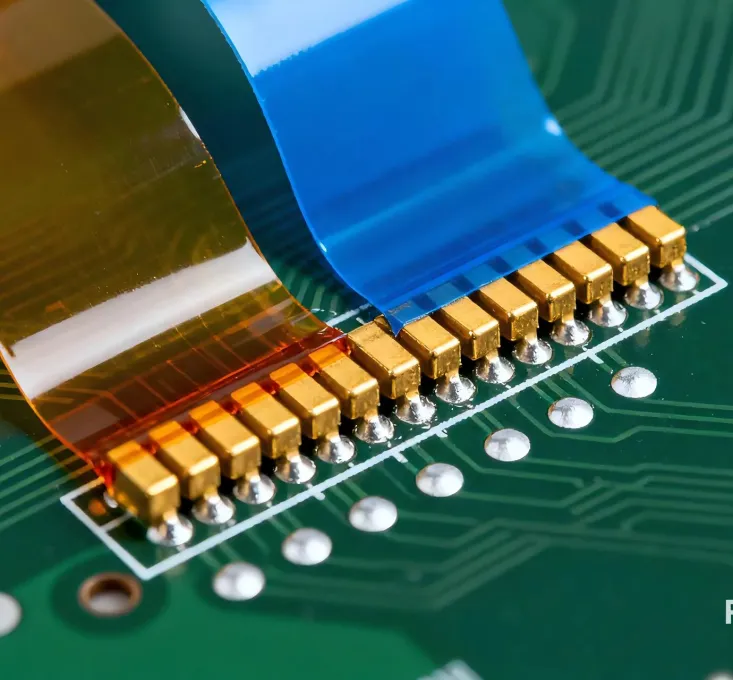

Polyimide tape / Kapton tape is a type of specialty adhesive tape made with polyimide film as the base material, coated on one side with a high-temperature adhesive (such as silicone or acrylic). It features excellent resistance to high and low temperatures (-269℃ to +300℃), outstanding electrical insulation, strong chemical resistance, and leaves no residue after removal. It is widely used in industries such as electronics, semiconductors, lithium batteries, and aerospace.

Polyimide tape is crucial in electronic component production due to its excellent high-temperature resistance, insulation, and residue-free properties. It uses a high-temperature resistant polyimide film and a special pressure-sensitive adhesive to protect sensitive components from damage during high-temperature soldering processes (such as wave soldering)

PTFE tape is a tape made with a polytetrafluoroethylene film as its base material, and its surface typically has low friction and high-temperature resistance. Its main characteristics include: high-temperature resistance, usable in the range of -200℃ to +260℃ (and even higher for short periods); excellent insulation with high dielectric strength; strong chemical resistance, resisting acid, alkali, and solvent corrosion; low friction, with a smooth surface that prevents substances from sticking, facilitating sliding and protection; and non-flammability and aging resistance, making it suitable for long-term use with stable performance. PTFE material is widely used in aerospace, electronics, food processing, and packaging industries, providing reliable solutions for demanding environments.

PTFE has a very high dielectric strength and a low dielectric constant, making it an ideal electrical insulating material. When manufacturing high-frequency circuits, microwave devices, high-performance cables, and connectors, PTFE films and coatings can provide excellent electrical insulation, reduce signal loss, and ensure stable performance in high-temperature and humid environments