In today’s world, where the wave of new energy vehicles is sweeping across the globe, range, safety, and fast charging are the focal points for every consumer and manufacturer. We deeply understand that creating a high-performance, highly safe power battery is an extremely complex system engineering task and a rigorous test of energy density, cycle life, thermal management, and collision safety.

1. Why must the battery system be ‘zero-tolerance’ for every component?

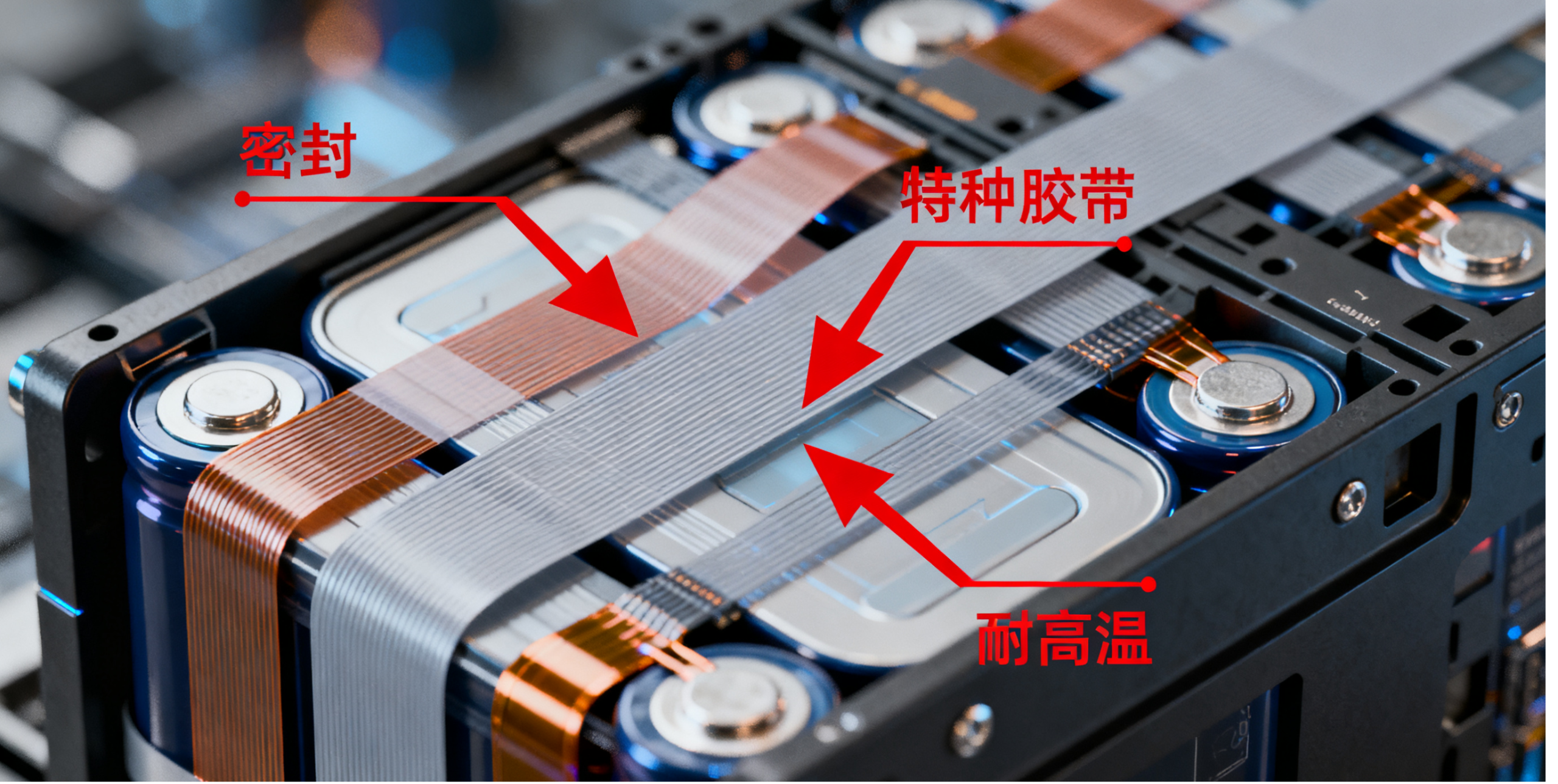

Safety is a ‘veto’: The battery pack contains tremendous energy, and any minor short circuit or loosening could trigger thermal runaway with unimaginable consequences. Therefore, the system must have extremely high electrical safety and physical stability. Reliability is the ‘lifeline’: The battery needs to operate stably in extreme temperatures from -30°C to over 50°C and withstand 8–10 years of usage and thousands of charge-discharge cycles, placing stringent automotive-grade requirements on the durability and consistency of every component. Performance is the ‘core competitiveness’: Higher energy density (range) and more efficient heat dissipation (fast charging and longevity) all stem from meticulous attention to every gram of weight and every inch of space within the system. This means that not only the core materials but also every auxiliary aspect—including connections, fixing, insulation, and thermal conduction—must be flawless. And this is precisely where specialty tapes shine.

II. Small Tape, Big Mission: Playing a Key Role in a Strict System

1. High safety requirements, so the tape must be reliably flame-retardant

Batteries are sensitive to heat and can malfunction. Therefore, the tape used for securing cells and insulating tabs must act as a flame-retardant guardian. Its role is not to fuel fire, but to serve as a barrier that stops or slows down flame spread in extreme circumstances.

2. High reliability requirements, so the tape must be stable and aging-resistant

Batteries are expected to last over ten years, enduring vibration, impact, and thermal cycling during that time. Ordinary tapes can age, peel, and fail. Battery tape must maintain adhesion and stability under extreme temperatures from -40℃ to 90℃, neither peeling nor slipping, serving as the “reinforcement” for long-term structural stability of battery cells.

3. Harsh chemical environment, so the tape must resist electrolyte corrosion

The interior of a battery contains highly corrosive organic electrolytes. Ordinary tape can dissolve, swell, or lose functionality. Battery tape must withstand long-term exposure to electrolyte, ensuring insulation layers do not fail and preventing internal shorts caused by corrosion.

4. Space is extremely valuable, so the tape must be thin yet strong

Every inch in battery design counts. The tape must provide sufficient insulation strength, adhesion, and puncture resistance in a very thin form, quietly taking on multiple responsibilities within limited space.

Details determine success or failure. On the path to breakthroughs in battery technology, the reliability of every component is crucial. Zhejiang ROBO New Material is ready to be your most reliable partner, using our seemingly small but essential products to safeguard the safety and performance of new energy batteries and support the healthy development of the industry.

If you are looking for reliable specialty tape solutions for your battery design, we welcome you to contact us for professional technical consultation and sample support.