Using 10,000 Hours of Verification as a Stepping Stone to Benchmarking: Ripo Materials’ Growth and Improvement Under NCC’s Audit.

When the Nippon Chemi-Con (NCC) audit team appeared at the Rebo New Materials factory, the air in the entire workshop seemed to gain a touch of “professional rigor”—after all, this group came from the world’s number one aluminum electrolytic capacitor industry giant, holding nearly 30% market share in the field, and defining capacitor performance standards from automotive electronics to industrial equipment. As a technical participant throughout the entire process, this two-day “industry benchmark audit” allowed me to truly feel the world’s top supply chain’s dedication to “ultimate quality.”

This audit, which garnered company-wide attention, had quietly begun several months prior. When Nippon Chemi-Con (NCC) sent the audit schedule to Rebo New Materials, we were both confident because “the electronic tape passed Nippon Chemi-Con’s 10,000-hour lifespan verification,” and even more so because we were facing the rigorous testing of an industry benchmark—it’s well known that Nippon Chemi-Con’s supply chain audits are renowned for their “attention to detail and systemic penetration,” with every link, from product performance to management processes, potentially becoming the focus of the examination.

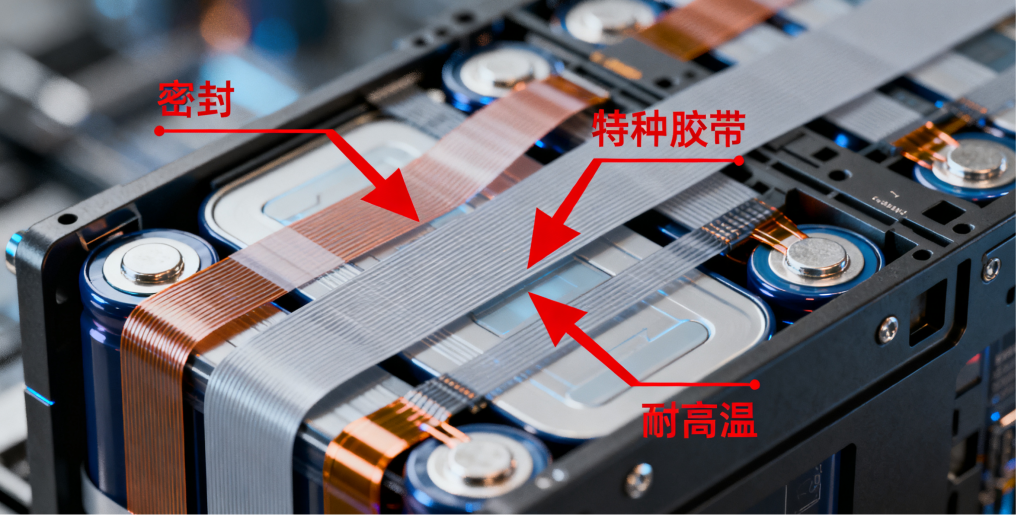

During the preparation period, our team meticulously refined our work, almost “using Guimigong’s standards as a mirror.” The audit checklist we received was 37 pages long, covering not only the raw data from the 10,000-hour (125℃ high temperature, 85% humidity) accelerated life test of the electronic tape and the adhesive formulation stability report, but also detailed electrostatic protection records in the production workshop, temperature and humidity monitoring curves in the raw material warehouse, and even customer complaint handling records from the past year. We didn’t simply “prepare according to the list,” but proactively compared our work with Guimigong’s publicly available “Supply Chain Quality Management Manual,” extending the batch traceability process for the electronic tape from three levels—”finished product – production batch – raw material”—to four levels—”finished product – production batch – raw material – supplier batch.” We also specifically identified “five technical pain points we wanted to consult the audit team about,” such as “the electrolyte corrosion resistance test method for tape used in high-voltage capacitors.” This proactive approach of “identifying gaps in advance and seeking guidance” made document communication during the pre-audit phase exceptionally smooth.When the Guimigong audit team finally entered the Zhejiang Ruibo New Materials factory, our feelings were more like “students awaiting teacher inspection”—expecting to expose shortcomings through professional dialogue, and even more so, eager to learn the true essence of management from the industry leader. This audit was not a simple “qualification pass,” but a “practical classroom” for learning from benchmarks and promoting continuous improvement. We always maintained a humble attitude, seeking possibilities for improvement in every detail.

Every detail of the on-site audit contained an “opportunity for growth.” In the electronic tape coating workshop, Team Leader ST’s gaze lingered on the precision display screen of the slitting process: “The current slitting error of ±0.1mm, while meeting general standards, would be more suitable for our automated production line if it could be reduced to ±0.05mm for the core assembly of high-precision capacitors.” As soon as he finished speaking, our production team immediately gathered around to take notes, not only asking about the parameters of Guimigong’s production line slitting equipment, but also proactively inquiring about “how to control error accumulation through a tool wear warning mechanism.” Section Chief LM showed us the “Tool Life Management Ledger” from the Guimigong factory on his phone. Our equipment supervisor immediately took a picture of the template and planned to organize departmental training the next day.

The laboratory verification process further highlighted the gap in “data rigor.” When the SK auditor reviewed the 10,000-hour life test records, he pointed out that “the existing data only records the initial and final adhesion. Adding intermediate data every 2,000 hours would better reflect the tape performance degradation pattern.” Our test engineer didn’t argue that “industry practice only requires initial and final data,” but immediately questioned Guimigong about its “data acquisition density standards” for different application scenarios (such as automotive electronics and industrial power supplies), and adjusted the test record template on the spot—after all, rather than simply “conforming to conventions,” Reipo aimed to “match the benchmark.”

The value of the audit lies in its profound impact on the management system. When Gui Migong mentioned that “the annual audit of core raw material suppliers should include an assessment of ’emergency capacity reserves’,” we realized that our supplier management only focused on “quality stability,” neglecting supply assurance in extreme situations. The procurement team immediately consulted the auditor about Gui Migong’s “supplier emergency assessment indicators” (such as the capacity ratio of alternative suppliers and response time) and planned to revise the “Core Raw Material Supplier Audit Checklist” by the end of the month. This inspiration, moving from the “product level” to the “management level,” is the most valuable gift the audit brought us.

At the closing meeting, Section Chief LM described Ruibo as a “potential growth partner” and listed three improvement suggestions: optimizing the short-term temperature resistance stability of electronic tape at 150℃, reducing slitting process errors, and improving supplier emergency management. Faced with these suggestions, we didn’t rush to commit to deadlines but first confirmed the details one by one—for example, consulting Section Chief LM about “the specific pressure conditions for the 150℃ temperature resistance test” and “the weighting allocation for supplier emergency assessments”—until every question was clarified before developing a 90-day rectification plan based on the actual situation. In his concluding remarks, our General Manager frankly stated, “The 10,000 hours of validation is a testament to our past achievements, but the ‘extreme attention to detail’ and ‘systematic management thinking’ we learned from Guimigong today are the keys to Rebo’s future growth.”

As the audit team departed, our Technical Director clutched a thick notebook—filled with Guimigong’s suggestions, equipment parameters, and management methods. For Rebo, the end of this audit marks the beginning of continuous improvement: we have established a dedicated improvement team, breaking down each suggestion into concrete actions, from precision adjustments to the adhesive application equipment to optimization of the supplier audit process, taking one step at a time to reach the benchmark. After all, in the “small but sophisticated” field of electronic tape, only by humbly navigating and relentlessly pursuing improvement can we keep pace with the world’s top supply chains.