In fields such as industrial manufacturing, electronic packaging, and new energy, tape has evolved from a simple adhesive tool into a key material that affects product reliability, safety, and production efficiency. A single adhesive failure can lead to product malfunction, production line stoppage, or even safety accidents. Therefore, establishing a scientific tape quality evaluation system is crucial.

1. Basic Physical Properties: The “Baseline” of Quality

– Initial Adhesion: Indicates the tape’s ability to create an instant bonding effect upon initial contact with the surface, directly affecting the efficiency and yield of automated application.

– Holding Power: Evaluates the tape’s inherent ability to resist shear displacement under sustained constant stress (i.e., cohesive strength). Insufficient performance in this aspect can cause components to loosen during long-term use.

– 180° Peel Strength: The core quantitative indicator of adhesion strength, referring to the force required to peel the tape from a test plate at a 180-degree angle at a standard speed (unit: N/25mm), directly reflecting the firmness of the adhesion.

2. Functional Capabilities: The “Skills” to Handle Complex Environments

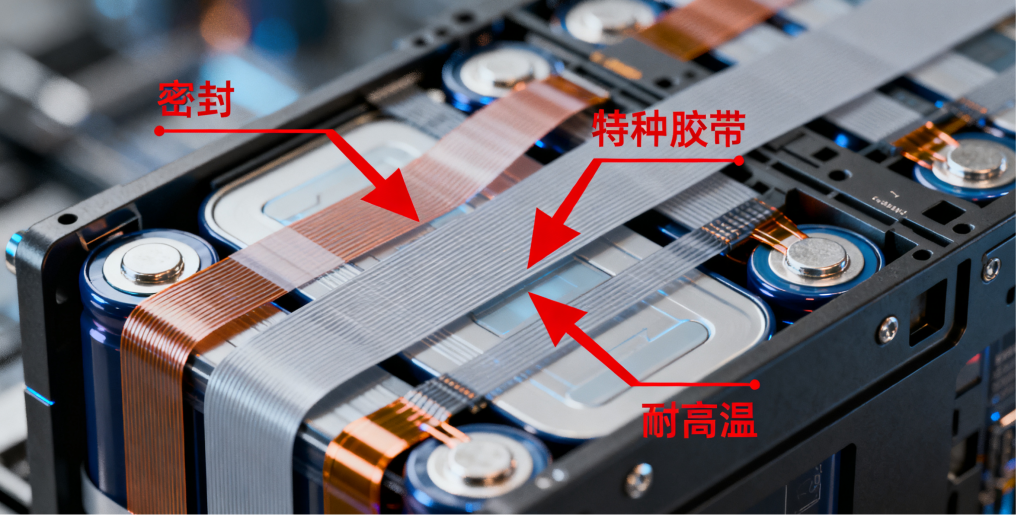

– Temperature Resistance: This is the core of high-temperature tape. The long-term usage temperature and short-term peak temperature must be clearly defined. Poor-quality tape can fail, melt, or leave stubborn residue under high temperatures.

– Chemical Resistance: Assess whether the tape swells, softens, peels, or loses performance after contact with specific chemicals (such as solvents, grease, or electrolytes).

– Insulation Strength: Crucial for electronic and electrical applications, this refers to the maximum voltage the tape can withstand before breakdown (unit: kV/mm). High-quality electrical tape must have high and stable insulation strength.

3. Material and Process Stability: The ‘Internal Strength’ of Quality

– Substrate Strength and Uniformity: Whether the substrate (such as PI, PET) is of even thickness, free of defects, and tear-resistant. Poor-quality substrates are prone to breaking under stress.

– Uniformity of Adhesive Coating: Whether the adhesive layer is smooth, free of particles and bubbles. Uneven coating can cause fluctuations in bonding strength, resulting in a “striped” bonding phenomenon.

– Storage Stability: High-quality tape can maintain its performance without significant decline for a long time (usually over a year) under specified storage conditions (such as light-free, cool environments).

Evaluating the quality of a roll of tape is a systematic process integrating materials science, application technology, and quality management. At Zhejiang Ruibo New Materials Co., Ltd., we not only provide tape products that meet strict standards but are also committed to being your strategic partner, offering comprehensive technical support from material selection and performance testing to process optimization.