Who We Are

Our capacitive tapes deliver precise, reliable, high-temperature resistant solutions across electronics, automotive, and high-precision industries.

- Home

- Who We Are

Material Innovator

- Established in 2010, ROBO currently has 80 employees and is a high-tech manufacturing enterprise focused on the research and development of new materials for the electronics and new energy industries.

- We have a trusted materials R&D team and highly skilled coating technology experts, equipped with advanced industry-leading machinery for mixing, coating, slitting, rewinding, winding, and testing.

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

Founded In

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

Building Area

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

Customers

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

Current Employees

Basic Information

- ROBO has established textile production bases in Zhejiang and Jiangsu provinces, including a newly built 22,000-square-meter production base in Longyou, Zhejiang, with an annual production capacity of up to 100 million square meters. Within the base, multiple automated production lines, slitting machines, winding machines, rewinding machines, and other advanced equipment are installed, creating an integrated production process encompassing film handling, pretreatment, automatic glue supply, precision glue application, online thickness detection, defect detection, and lamination, ensuring the superior quality of every roll of tape. The top-tier materials R&D team and welding technology experts at ROBO New Materials have successfully served over 1,000 companies for three consecutive years, earning widespread recognition and praise.

Corporate Culture

Committed to integrity and excellence, our team delivers globally compliant PVC solutions with consistent quality.

Innovation-Driven Growth

- Continuously advance material research and technology to lead the development of the electronics and new energy industries.

Quality and Reliability

- Commit to delivering high-performance, consistent, and trustworthy products that create long-term value for our customers.

Sustainable Future

- Promote green manufacturing and energy-efficient solutions, contributing to a cleaner and more sustainable world.

Development History

From early breakthroughs to today’s achievements, each milestone highlights our steady progress, innovative drive, and long-term commitment to excellence.

2010-2011

Kunshan ROBO was founded, transitioning from trade to manufacturing with a complete production system and advanced equipment.

2012-2016

Led domestic breakthroughs in capacitor adhesives, capturing top market share and partnering with industry leaders.

2017

Holds 19 patents. Established a Shenzhen office to expand in South China and build an integrated R&D, production, and service system.

2018-2019

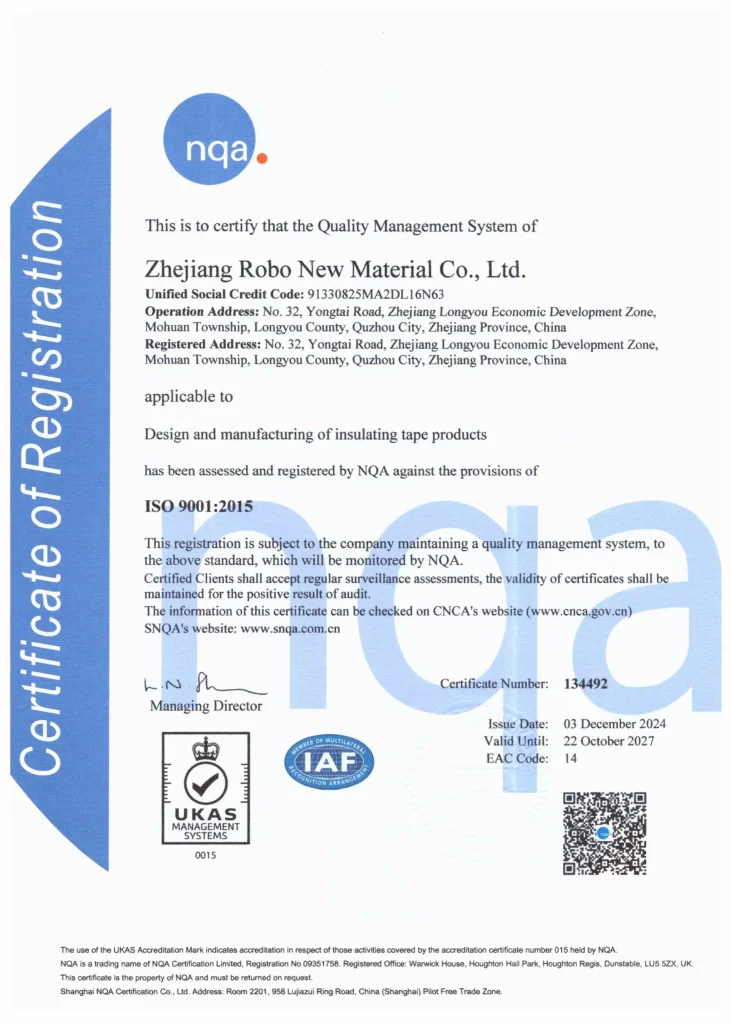

ISO9001-certified Jiangsu tech enterprise. Expanded to Zhejiang, entered lithium batteries, partnered with industry leaders.

2020-2022

Kunshan recognized as a national high-tech enterprise, upgraded its brand, ISO14001-certified, and serves top photovoltaic companies.

2023-2024

The construction of the Longyou Intelligent Base will increase production capacity by 300%. The product has obtained automotive-grade certification and UL certification, and partners with Fortune 500 companies.

2025

Launching the "Global Excellence Program": Building a brand matrix, establishing a research institute to develop intelligent systems, expanding overseas channels, and becoming an industry leader.

Our Office Environment

A modern, well-equipped office designed for collaboration and productivity, featuring open workspaces, meeting rooms, and comfortable facilities.

Certifications & Credentials

Committed to integrity and excellence, our team delivers globally compliant PVC solutions with consistent quality.

Together We Achieve: Global Partnerships in Action

Core Technology

Glue formula

Independent development and continuous innovation

Coating process

Stabilize existing processes and continuously innovate new products

Cleanroom

Dry and 10,000-grade cleanrooms for diverse production needs

Applied Research

Research customer needs and applications and propose solutions

Quality Control

Incoming material inspection, production inspection, and outgoing inspection to ensure quality.

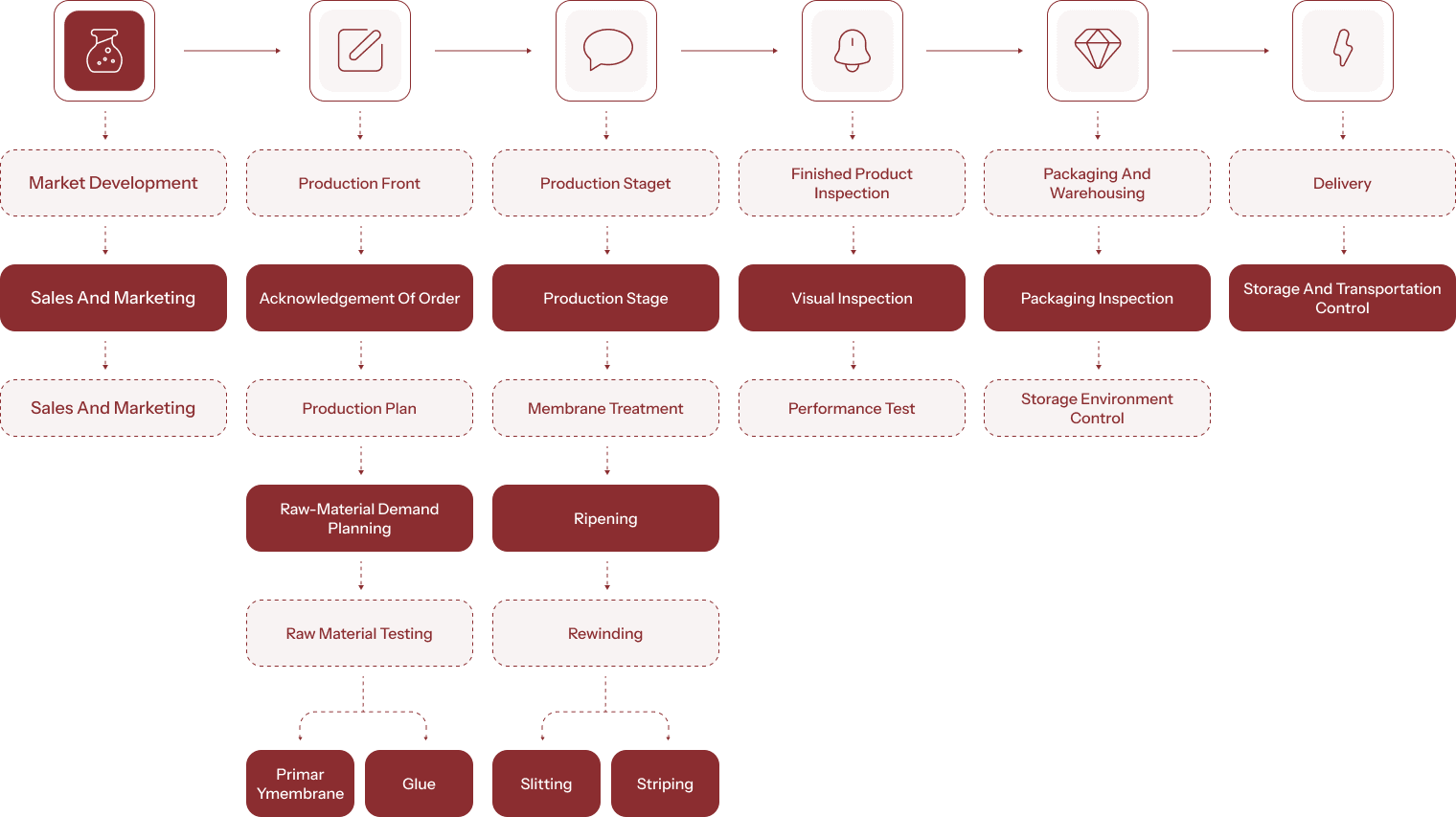

Our Comprehensive And Efficient Workflow Process

Production Equipment

High-precision coating equipment

With micron-level precision and stable performance, it ensures consistent quality for every batch of tape, adapting to all scenarios from general packaging to high-end electronics and medical applications. Coating thickness control accuracy reaches ±1μm, and lateral uniformity error is ≤2%, far exceeding industry standards. It supports high-speed coating up to 300m/min, coupled with an automatic feeding and non-stop winding design, significantly increasing production capacity and avoiding material waste.

01

02

03

04